SINTERED BRAKE PADS SINTERED IN OPEN BELT FURNACE

LOOK UP YOUR BIKE TO FIND RELEVANT BRAKE PARTS

Lookup your bikeMost newer motorcycles are equipped with sintered brake pads.

Friction material slowly moves

SBS uses two basic methods for sintering of friction materials:

Sintering of friction materials is very different compared to hot pressing of ceramic/organic friction materials. Typically the pressure used for sintered friction materials is 10 times higher compared to ceramic/ organic friction materials.

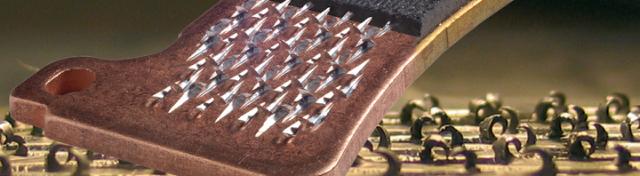

In the sintering process the friction material slowly moves through an open belt furnace, where it is heated to 800°C, or more. During the time in the furnace, the metal particles melt together and creates a metal matrix - known as sintering. Within this metal matrix there are inclusions of abrasive or lubricating particles, which at the end creates the friction material. SBS brake pads produced in an open belt furnace are either brazed to the back plate or feature NRS technology for adhesion.

CONDUCTIVE SINTERING

Conductive sintering or direct hot pressing is a technology based on the principle of heating up the material by electrical current. The advantages of this method is that it is very easy to control the sintering process resulting in an excellent and homogenous brake pad material quality.

For conductive sintered products, NRS retention technology is used.

COATING

SBS only uses coating materials and methods that protects the brake pads optimally against corrosion.

Copper and Chromium-Nickel temperature stability of 900°C.